If you’ve ever mixed or tested a sanitizer and wondered, “What should the ppm be for sanitizer solution?”, you’re not alone. Whether you work in food service, healthcare, or general cleaning, knowing the right parts per million (PPM) ensures your sanitizer is strong enough to kill germs — but not so strong that it damages surfaces or becomes unsafe.

This guide explains the ideal sanitizer ppm range, why it matters, and how to test and adjust it accurately.

What Is PPM in a Sanitizer Solution?

PPM (parts per million) measures how concentrated a sanitizer or disinfectant is in a solution.

It tells you how many parts of active chemical (like chlorine or quaternary ammonium) exist in one million parts of water.

For example:

- A chlorine sanitizer at 100 ppm means there are 100 mg of chlorine per liter of solution.

- A quat sanitizer at 200 ppm has 200 mg of active compound per liter.

To understand how ppm fits into general chemistry measurements, see our PPM Glossary.

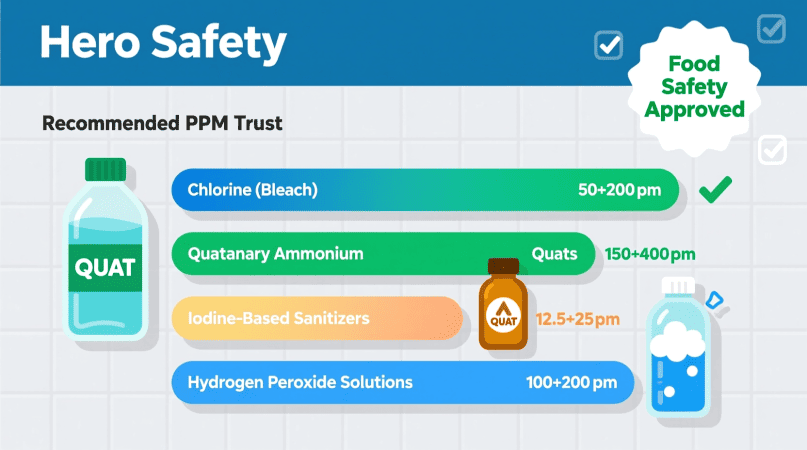

Recommended PPM Levels by Sanitizer Type

Different sanitizing agents require different ppm strengths for effectiveness. Below are standard ranges widely accepted in food safety and laboratory hygiene.

| Sanitizer Type | Recommended PPM | Typical Use |

|---|---|---|

| Chlorine (bleach-based) | 50 – 200 ppm | Food-contact surfaces, kitchenware, water sanitation |

| Quaternary Ammonium (Quats) | 150 – 400 ppm | General disinfection, countertops, non-food contact areas |

| Iodine Sanitizer | 12.5 – 25 ppm | Bar glass sanitizing, soft-serve equipment |

| Hydrogen Peroxide | 100 – 300 ppm | Surface and equipment disinfection, healthcare settings |

| Peracetic Acid (PAA) | 150 – 200 ppm | Brewery, dairy, and food-processing environments |

👉 You can verify or calculate these values using our Bleach PPM Calculator or Hydrogen Peroxide PPM Calculator.

How to Calculate the Correct PPM for a Sanitizer

The general ppm formula applies to all chemical dilutions:

PPM= Mg of Solute / L of Solution

When using concentrated sanitizer:

- Multiply the percentage of active ingredient by 10,000 to get ppm of the concentrate.

- Then divide by your desired ppm level to find how much concentrate you need to add to water.

Example:

A bleach product has 5% sodium hypochlorite.

That equals 50,000 ppm available chlorine (5 × 10,000).

If you want a 100 ppm solution, you’ll mix:

100 / 50,000 = 0.002 L concentrate per liter of water

That’s 2 mL bleach per liter of water.

You can confirm your dilution instantly using the Chemical Dosing PPM Calculator.

Why Maintaining the Right PPM Matters

Maintaining sanitizer ppm within the recommended range ensures:

- Effectiveness – enough active ingredient to kill bacteria and viruses.

- Safety – too high a concentration can leave residue or cause irritation.

- Compliance – meets local food safety or health-department regulations.

A sanitizer that’s too weak won’t disinfect surfaces, and one that’s too strong can damage equipment or contaminate food contact areas. Regular testing helps avoid both extremes.

How to Test PPM in Sanitizer Solutions

Testing sanitizer strength only takes a minute and helps maintain accuracy during daily use.

- Use test strips or digital meters.

These provide color-change or numeric readings of ppm concentration. - Dip for 5 seconds.

Submerge the strip or probe into the mixed sanitizer and compare results to the color chart or meter display. - Adjust concentration as needed.

- If too low, add small amounts of sanitizer concentrate.

- If too high, dilute with clean water.

- Check frequently.

Sanitizer strength drops over time due to evaporation, organic matter, and temperature changes.

If you often need to fine-tune ppm values, the PPM Solution Calculator makes quick adjustments easy.

Factors That Affect Sanitizer PPM

- Temperature:

Chlorine and peroxide sanitizers lose strength at high temperatures. Use cool or room-temperature water when mixing. - pH levels:

Highly alkaline water can reduce chlorine effectiveness; acidic water can increase reactivity. - Organic matter:

Food debris, grease, or dirt rapidly neutralize sanitizer chemicals. Always clean before sanitizing. - Storage time:

Mixed sanitizer solutions degrade over hours or days, depending on the agent.

Typical PPM Standards for Food and Hygiene Safety

Food-safety organizations and regulatory bodies recommend the following general ppm levels:

- Food-contact sanitizing (chlorine): 100 ppm minimum

- Dish machine sanitizer rinse: 50–100 ppm

- Hand or utensil dips (quats): 200 ppm

- Surface sanitizing (iodine): 25 ppm

Always follow manufacturer guidelines and local health-code requirements for your specific sanitizer type.

Frequently Asked Questions

What happens if sanitizer ppm is too low?

The solution may not kill harmful microorganisms effectively, leading to contamination.

What if it’s too high?

It can corrode metals, irritate skin, and leave chemical residues on food contact surfaces.

Can I mix different sanitizers?

Never. Mixing chemicals like chlorine and ammonia can create dangerous fumes.

How often should sanitizer ppm be checked?

Test at least once per shift or whenever the solution looks dirty or cloudy.

Matthew is a chemical technology enthusiast and the creator of PPMCalculator.com — a platform dedicated to simplifying complex concentration and conversion formulas for students, researchers, and industry professionals. With years of experience exploring water chemistry, environmental monitoring, and laboratory analysis, he focuses on making scientific accuracy both practical and accessible.

When not writing or developing new tools, Shimul enjoys testing real-world chemical measurements, refining calculator algorithms, and helping learners understand the science behind PPM, EC, and TDS.