In manufacturing and process control, quality engineers often talk about PPM (parts per million) as a measure of defect rate or performance.

If you’ve ever wondered how to calculate ppm in quality, this guide will help you understand the formula, apply it to real data, and interpret what your ppm number means for your product or process.

What Does PPM Mean in Quality?

In chemistry, ppm represents parts per million of a substance in a solution.

In quality management, ppm means the number of defective units out of one million produced.

It’s a standardized way to measure how often errors or defects occur — the lower the ppm, the better your process quality.

Example:

If a factory makes 1,000,000 bolts and 50 are defective, the ppm is 50.

That means 50 out of every million bolts do not meet quality standards.

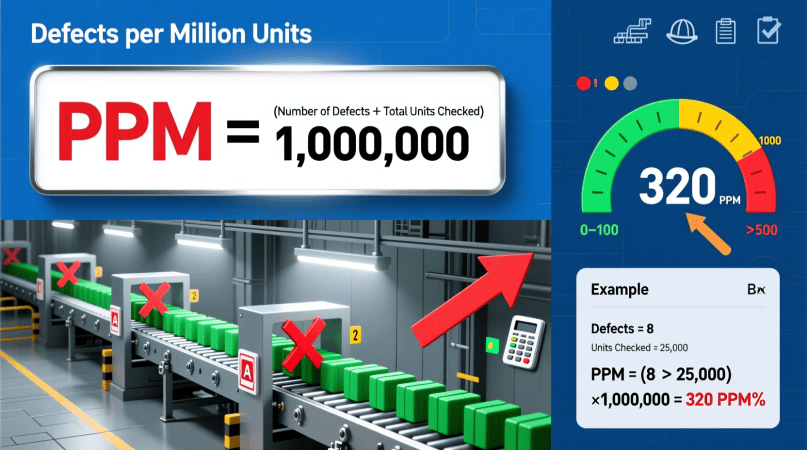

PPM Formula for Quality Calculations

The basic formula for ppm in manufacturing quality is:

PPM= Number of Defective Units / Total Units Produced ×1,000,000

This converts the defect proportion into a “per-million” metric.

Example Calculation

A company produces 200,000 circuit boards, and 12 have defects.

PPM} = 12/200,000× 1,000,000 = 60

✅ The defect rate is 60 ppm — a strong indicator of high quality.

To double-check or automate your math, use the PPM Accuracy Calculator.

Understanding PPM and Percent Defective

You can easily convert between ppm and percent defective:

Percent Defective = PPM/10,000

PPM=Percent Defective×10,000

Example:

If your defect rate is 0.005 %, then:

0.005×10,000=50ppm

This means that 0.005 % defective = 50 ppm.

You can verify these conversions using our PPM to Percent Calculator.

Why PPM Matters in Quality Management

PPM provides a clear, comparable way to express performance across production lines or suppliers.

Benefits:

- Benchmarking — compare defect levels between processes or plants.

- Supplier evaluation — measure external vendor quality.

- Continuous improvement — track defect reduction progress over time.

- Customer reporting — present standardized data using recognized quality language.

For industries like automotive, aerospace, electronics, ppm reporting is mandatory within ISO 9001 or Six Sigma quality frameworks.

Relation Between PPM, CPK, and Six Sigma

In process capability studies, ppm is often related to Cpk (Process Capability Index).

A higher Cpk means a more capable process, producing fewer defects (lower ppm).

Approximate relationship:

| Cpk | Sigma Level | Defects per Million (PPM) |

|---|---|---|

| 1.0 | 3σ | 2,700 ppm |

| 1.33 | 4σ | 63 ppm |

| 1.67 | 5σ | 0.6 ppm |

| 2.0 | 6σ | 0.002 ppm |

You can convert directly between capability and defect rate using our Cpk to PPM Calculator.

This helps teams connect process stability with measurable quality outcomes.

Real-World Example: Calculating PPM in a Production Line

Let’s look at an example from a plastic molding plant.

- Total parts produced per week: 350,000

- Rejected parts: 84

Step 1: PPM= 84/350,000× 1,000,000 = 240 ppm

Step 2:

Interpretation: Out of every million parts, 240 fail inspection — an overall yield of 99.976 %.

Step 3:

If your target is 100 ppm, the process must reduce rejects by about 65 %.

This is where corrective action, process improvement, or statistical control (like SPC) come in.

For insight into precision and error reduction, see our PPM Calculation Mistakes Guide.

Using PPM as a Quality KPI

PPM can be tracked over time as a Key Performance Indicator (KPI) to monitor improvement.

You can visualize weekly or monthly ppm trends and tie them to process adjustments.

Example Targets:

- Automotive industry: ≤ 50 ppm

- Consumer electronics: ≤ 100 ppm

- Packaging materials: ≤ 500 ppm

- General manufacturing: ≤ 1,000 ppm

The ultimate goal is to move toward a Six Sigma level, or 3.4 ppm defects, which represents world-class process quality.

For additional perspective, explore how ppm fits into continuous improvement via the PPM to CPK Calculator.

Common Questions

1. What does 100 ppm mean in quality?

It means 100 defective parts per million produced — or a defect rate of 0.01 %.

2. Is lower ppm always better?

Yes. A lower ppm indicates fewer defects and a more capable process.

3. How often should ppm be measured?

Many plants track ppm daily or per batch to ensure consistency across shifts or suppliers.

4. Can I calculate ppm from scrap percentage?

Yes. Multiply scrap % × 10,000 to get ppm.

Example: 0.07 % scrap = 700 ppm.

Matthew is a chemical technology enthusiast and the creator of PPMCalculator.com — a platform dedicated to simplifying complex concentration and conversion formulas for students, researchers, and industry professionals. With years of experience exploring water chemistry, environmental monitoring, and laboratory analysis, he focuses on making scientific accuracy both practical and accessible.

When not writing or developing new tools, Shimul enjoys testing real-world chemical measurements, refining calculator algorithms, and helping learners understand the science behind PPM, EC, and TDS.