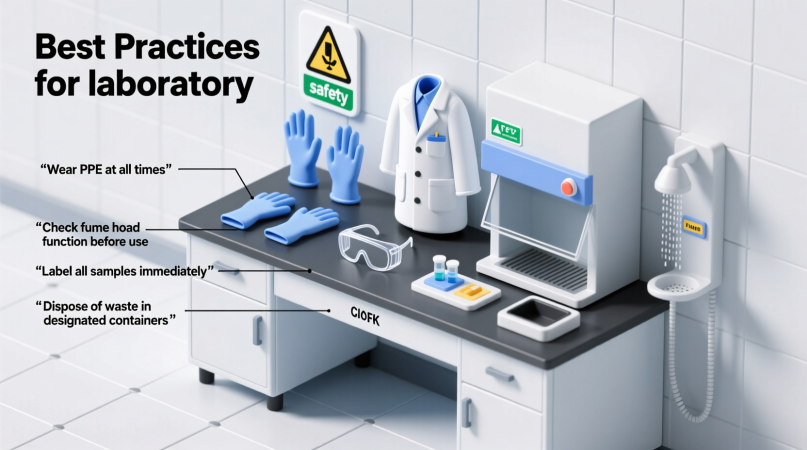

Best Practices for PPM Measurements in Laboratory Work

Accurate PPM (parts per million) measurements are essential for laboratory success, whether you’re testing water quality, analyzing environmental samples, or ensuring compliance in food and pharmaceuticals.

Because PPM quantifies trace levels of substances, even small mistakes can lead to significant errors in data, impacting research outcomes and regulatory compliance. This guide shares proven best practices for reliable, reproducible PPM measurements in any laboratory setting.

Why PPM Precision Matters in the Lab

The Role of PPM in Laboratory Analysis

PPM is a standard unit for measuring very low concentrations of chemicals, metals, or contaminants in samples. Laboratories rely on precise PPM readings to:

- Meet regulatory standards (e.g., for drinking water, air, or food safety)

- Monitor environmental pollution

- Control product quality in manufacturing

- Support research and development

Common Laboratory Applications

- Water and wastewater testing

- Environmental monitoring

- Pharmaceutical quality control

- Food and beverage safety analysis

- Chemical process management

Key Best Practices for PPM Measurements

1. Calibrate Equipment Regularly

Why Calibration Is Critical

- Accurate PPM measurements depend on properly calibrated instruments—such as TDS meters, spectrophotometers, or ion-selective electrodes.

- Use certified calibration standards, and follow the manufacturer’s recommendations for frequency.

Tip: Always calibrate before a new set of measurements or after changing reagents.

2. Use High-Quality Reagents and Standards

- Select analytical-grade reagents and certified reference materials.

- Check expiration dates and store chemicals as recommended to prevent degradation.

3. Prepare and Handle Samples Carefully

Sample Integrity

- Use clean, contaminant-free glassware and containers.

- Rinse equipment with distilled or deionized water between samples.

- Label samples clearly and keep a consistent chain of custody.

Want to avoid common pitfalls? Read PPM Calculation Mistakes.

4. Follow Standard Operating Procedures (SOPs)

- Use validated methods (such as EPA, ISO, or ASTM protocols).

- Document every step—including sample prep, reagent lot numbers, and instrument settings.

- Train staff regularly to ensure consistency and awareness of updates.

5. Pay Attention to Dilutions

- Accurately calculate dilution factors and record them in your lab notebook.

- Use high-purity water (deionized or distilled) for all dilutions.

- When in doubt, double-check calculations with the PPM Solution Calculator.

6. Control Laboratory Environment

- Temperature, humidity, and light can affect certain PPM analyses (especially for sensitive chemical reactions or spectrophotometry).

- Record environmental conditions during measurements and keep them consistent if possible.

7. Use Blanks and Quality Controls

- Blanks: Analyze blank samples (containing no analyte) to identify contamination or instrument drift.

- Quality controls (QC): Run samples with known PPM concentrations to verify accuracy and repeatability.

8. Interpret Results Against Standards

- Compare your PPM results to regulatory or scientific guidelines.

- For drinking water, review Safe PPM Levels for Drinking Water.

- Always report results with detection limits and measurement uncertainty.

9. Keep Thorough Documentation

- Log all measurements, calibration data, reagent batch numbers, and calculations.

- Good record-keeping supports reproducibility and regulatory compliance.

10. Review and Update Procedures Regularly

- Stay current with new methods, equipment, and regulatory changes.

- Periodically review and revise SOPs to reflect best practices.

Common Pitfalls and How to Avoid Them

Skipping Calibration

This introduces systematic error. Always verify instrument accuracy before use.

Incorrect Dilution Calculations

A small error in dilution can lead to large inaccuracies in PPM results. Use online tools like the PPM Solution Calculator for confidence.

Glassware Contamination

Even trace residues can skew low-level measurements. Use strict cleaning protocols and blanks to check for contamination.

Poor Sample Labelling

Mislabelled or mixed-up samples undermine data integrity. Always double-check labels and maintain a clear chain of custody.

For more troubleshooting, visit PPM Calculation Mistakes.

Frequently Asked Questions

How often should instruments be calibrated?

At minimum, calibrate before each new series of measurements or as specified by instrument guidelines.

Can I use a calculator for PPM dilutions?

Yes! The PPM Solution Calculator makes it easy to get dilution and concentration calculations right.

How do I ensure compliance with standards?

Follow validated methods, use certified standards, and compare results with guidelines like those at Safe PPM Levels for Drinking Water.

Dr. Robert is an industrial chemist specializing in process control, water purification, and quantitative chemical analysis. She has worked with environmental labs and manufacturing facilities to optimize solutions in parts-per-million (PPM) precision and safety compliance.

At PPMCalculator.com, Dr. Robert ensures the accuracy of each calculator and guide through peer review and data validation. Her mission is to make chemistry tools more reliable for engineers, researchers, and students worldwide.

Follow her professional updates on LinkedIn or contact via info@ppmcalculator.com. For More details, Click here